Modely: Revolutionize rebar inspection- just an iPad does it all!

Awarded the infrastructure DX grand prize(startup encouragement prize)by the Ministry of Land, Infrastructure, Transport and Tourism(In Japanese)

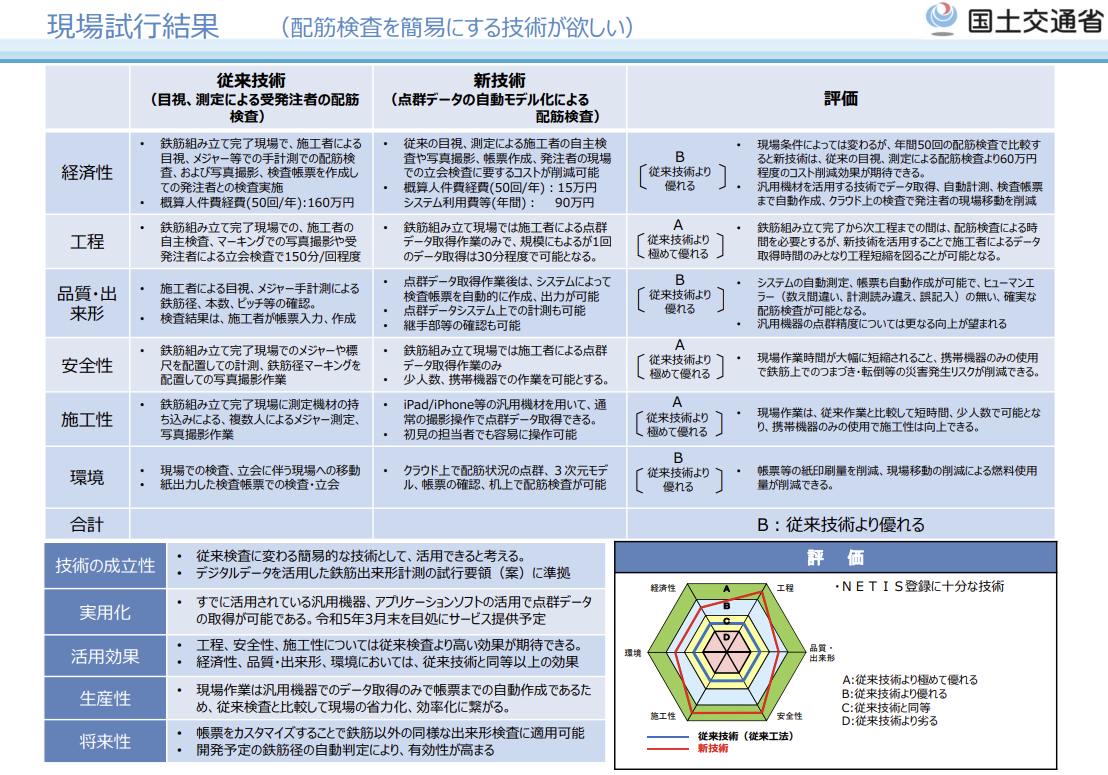

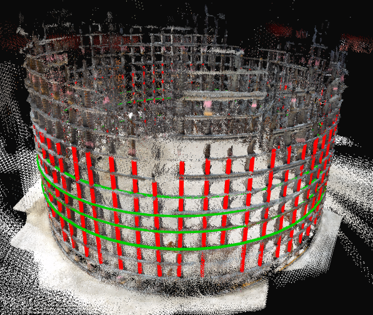

Modely scans rebars using an iPad or other LiDAR-equipped tools, converts the point cloud data into 3D models, and automatically generates rebar inspection reports. Modely is registered as 'New Technology' under the 'Guidelines for Digital Rebar Inspections' issued by the Ministry of Land, Infrastructure, Transport and Tourism (In Japanese), and has received a lot of positive feedback from users.

Modely significantly reduces the workload involved in rebar inspections, making the process more efficient and streamlined. It also supports various inspection items, such as double reinforcement, hoop rebar and cover thickness. In the long term, the models generated by Modely can contribute to future maintenance management of structures.

NETIS Registration No. CB-230008-VE (In Japanese)

Registered as a 'New Technology' by the Ministry of Land, Infrastructure, Transport and Tourism

180+ businesses have used our service !

CMYK.png?width=2000&height=414&name=%E5%8A%A0%E5%92%8C%E5%A4%AA%E3%83%AD%E3%82%B4(%E3%82%B9%E3%83%AD%E3%83%BC%E3%82%AC%E3%83%B3%E5%85%A5%E3%82%8A)CMYK.png)

.jpg?width=802&height=559&name=%E8%8B%B1%E6%96%87%E3%82%AB%E3%83%A9%E3%83%BC_(%E6%8A%80%E5%B7%A5%E5%9B%A3%E3%83%AD%E3%82%B4).jpg)

.jpg?width=2000&height=1023&name=%E3%83%AD%E3%82%B4%E3%83%9E%E3%83%BC%E3%82%AF_black(%E5%B7%A5%E8%97%A4%E5%BB%BA%E8%A8%AD%E6%A0%AA%E5%BC%8F%E4%BC%9A%E7%A4%BE).jpg)

.png?width=807&height=200&name=%E5%9C%8B%E5%A0%B4%E7%B5%84%E3%83%AD%E3%82%B4(%E3%83%90%E3%83%8A%E3%83%BC%E7%94%A8).png)

%26%E3%82%BF%E3%82%B0%E3%83%A9%E3%82%A4%E3%83%B3.jpg?width=2000&height=703&name=%E3%82%B3%E3%83%BC%E3%83%9D%E3%83%AC%E3%83%BC%E3%83%88%E3%83%96%E3%83%A9%E3%83%B3%E3%83%89%E3%83%AD%E3%82%B4%26%E7%A4%BE%E5%90%8D%E3%83%AD%E3%82%B4(%E6%A0%AA%E3%81%82%E3%82%8A)%26%E3%82%BF%E3%82%B0%E3%83%A9%E3%82%A4%E3%83%B3.jpg)

Overview

With just 1 iPad, reduce approximately 80% of the workload for rebar inspections!

-1.png?width=1920&height=1080&name=%E5%90%8D%E7%A7%B0%E6%9C%AA%E8%A8%AD%E5%AE%9A%E3%81%AE%E3%83%87%E3%82%B6%E3%82%A4%E3%83%B3%20(8)-1.png)

Modely enables approximately 40% cost*1 savings and 80% labor*2 savings, compared to conventional inspection methods. Regarding the inspection items and accuracy, Modely follows 'Guidelines for Digital Rebar Inspections' issued by the Ministry of Land, Infrastructure, Transport and Tourism' (In Japanese). Our technology has already been adopted and used for national and prefectural projects in Japan.

*1:Cost was estimated as the sum of labor, travel expenses, and other related costs, assuming 50 rebar inspections per year.

*2:Labor was estimated based on the time required for manual measurement, marking, photographing, onsite inspection, and other related tasks per inspection.

Initiatives with the Ministry of Land, Infrastructure, Transport and Tourism

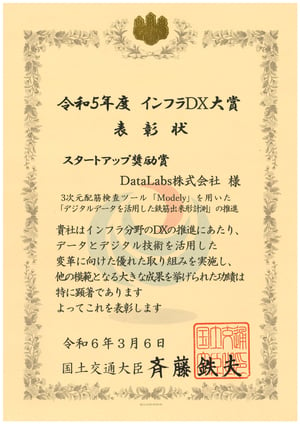

Right: FY2023 infrastructure DX grand prize (In Japanese)

In FY2022, our project with Modely was adopted in the Chubu Regional Development Bureau's initiative of matching businesses’ needs and technology seeds. Supported by authorities, accuracy verification was conducted on actual inspection sites. As a result, Modely was evaluated to be superior to conventional technologies. We have also held infrastructure DX seminars at the Kyushu Regional Development Bureau and the Chugoku Regional Development Bureau. Gaining experience in actual on-site operations with Modely, in 2024, DataLabs was awarded the infrastructure DX grand prize(startup encouragement prize)by the Ministry of Land, Infrastructure, Transport and Tourism.

Related Video (in Japanese):

"Capturing Point Clouds: Photographing the Bridge Pier "

To an iPad or another commonly available device, install point cloud acquisition applications such as PIX4Dcatch and Scaniverse. In general, PIX4Dcatch can measure larger areas compared to Scaniverse.

2. Convert Point Cloud Data to 3D Model

Related Video (in Japanese):

"Fully Automated Modeling: Specifying Target Areas"

Upload the acquired point cloud data to Modely, and select an area. 3D models will be generated.

3. Generate Reports

Related Video (in Japanese)

"Measuring Rebar with Modely: Count and Pitch"

Once the 3D models are generated, a report is automatically created. The report includes not only the comparison results between design and actual values but also a pass/fail assessment, both of which can be exported.

Please click Explore Modely to view examples of point clouds, the generated 3D models, and reports.

Measurement Capabilities of Modely

Double Reinforcement

Modely can automatically measure inspection items by generating 3D models from acquired point clouds. Even in the case of double reinforcement, measurement can be performed by simply selecting the areas for the front and back rebars, respectively.

Cover Thickness

%20-%20frame%20at%200m44s.jpg?width=1920&height=1020&name=%E3%81%8B%E3%81%B6%E3%82%8A%E5%8E%9A%E3%81%AE%E6%A4%9C%E6%9F%BB%20(1)%20-%20frame%20at%200m44s.jpg)

%20-%20frame%20at%201m45s.jpg?width=1920&height=1020&name=%E3%81%8B%E3%81%B6%E3%82%8A%E5%8E%9A%E3%81%AE%E6%A4%9C%E6%9F%BB%20(1)%20-%20frame%20at%201m45s.jpg)

Modely can generate 3D models from plane surfaces. Cover thickness from the formwork or floor can be measured by generating a 3D surface model of the formwork or floor.

Rebar Cages

Measurements can be performed for circumferentially aligned rebars, such as rebar cages, by specifying the inspection area. Modely can also measure rebar hoops.

Customer Testimonials

【Customer Testimonial】

We used Modely in our new station construction project, achieving approximately 70% labor savings by omitting manual photo documentation and streamlining the reporting process. We are impressed by its frequent updates, and excited about how it can further enhance scalability with 3D data!

DAITETSU KOGYO CO., LTD.& West Japan Railway Company【Customer Testimonial】

We used Modely in a construction project commissioned by Gunma Prefecture, achieving significant labor savings by eliminating the need for photo management and manual report creation. We explored point cloud acquisition using a laser scanner and successfully converted the data into 3D models.

We explored a new way of using Modely by experimenting with point cloud acquisition using a handy scanner with SLAM technology! In collaboration with a reseller company of Modely, Kabushikigaisha Sanyosokki, we are experimenting with various methods for point cloud acquisition.

IMAI CORPORATION

【Customer Testimonial】

We achieved over 60% labor savings in floor slab construction and are extremely satisfied with this system! Owners have acknowledged the accuracy of the rebar inspection. With 3D data capabilities, Modely enables accurate inspection of complex rebar configurations that are difficult to inspect using photo-based methods.

Yokogawa Bridge Corp.

【Customer Testimonial】

We highly recommend Modely as an effective tool for rebar inspection. It significantly reduces labor, achieving time savings that were difficult to realize with conventional photo-based tools. Inspection tasks that previously took an hour now require only about 15 minutes. We are impressed with its frequent feature updates and look forward to its continued development!

Fukudome Kaihatsu Kabushikigaisha

【Customer Testimonial】

Using Modely, we smoothly completed the entire process, from inspection arrangements to final delivery! Modely enables complex measurements that are difficult to perform with photo-based tools. We successfully conducted the inspection with the owner on-site, just one week after learning how to operate the tool.

UEKI CORPORATION

【Customer Testimonial】

Modely's owner invitation feature enables owners to view measurement data in the cloud, leading to considerable time and labor savings. Based on our experience, we can confidently recommend Modely to other companies. Although adopting a new tool required some adjustment in the beginning, we found it straightforward and easy to learn!

Kabushikigaisha Douwa Doboku

【Customer Testimonial】

Modely has allowed us to perform rebar inspections remotely. The number of photos we need to take has been reduced to one-fifth of what it was before. Overall, our productivity has improved, with work time decreasing to one-fourth, or even less! For instance, a task that used to require 30 minutes by two people now only takes 15 minutes by one person. Additionally, large scanning areas can be photographed in a single shot.

Sasaki Construction Co., Ltd.

【Customer Testimonial】

Modely streamlines rebar inspections, and we have high expectations for its contribution to future maintenance management. Inspection work that once took an hour by a few people now only requires 30 minutes by one person. A 3D view of the reinforcement can be generated using models, enhancing visibility and understanding. Both on-site staff and owners are satisfied with its usability.

Furugori Construction Co, Ltd.

Recommended Operating Environment:

| Device | 2020/2021 iPad Pro |

| OS |

Windows 10 (64 bits) or later |

| Memory | 8GB or more |

| Web browser | Google Chrome |

*Modely may function in environments that do not fully meet the recommended specifications mentioned above.

Visit Help Center for Modely user manual and more details!

Contact Us

.jpg?width=2000&height=1500&name=IMG_5817%20(1).jpg)